Engineering that Sourcing Your Competitiveness

At Kingtime, our cross-functional organizational structure has a clear goal: to harness and focus the energies and imagination of our people across the world on the detailed needs of individual customers.

Kingtime has the knowledge, experience, and credentials—qualities that have made us successful in the marketplace—to be there for you.

Our global experience and innovative thinking gives us a major advantage when it comes to providing the ultimate precision forging products and driveline system and solutions.

At the heart of Kingtime is a strong culture of operational excellence.

Learn More >

Main Business

Creating extra market value, maximizing value in at every stage of the process.

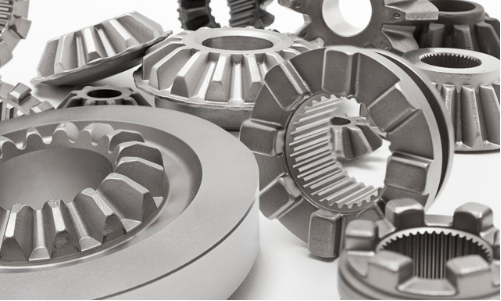

Hot & Warm Forgings

Focusing on key components for the transmission, chassis and suspension systems of passenger cars, commercial vehicles and heavy-duty vehicles, as well as key parts for engineering machinery, industrial robots, hydraulic systems, logistics industries etc.

Precision Forgings

Focusing on the OE Production of precision forging and machining for outer CV Joint, Inner CV Joint (including long rod), motor shaft (hollow), and high precision forged gear blanks.

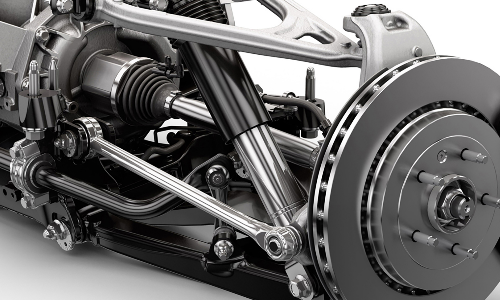

Driveline Products

Focusing on Out and Inner CV Joints, CV Axles, high performance transmission shaft and gears.

KINGTIME - WHERE IT ALL BEGINS

Focusing on precision forging and advanced machining

Who is KINGTIME?

Kingtime is well recognized as the leading blank forging developer and finished product manufacturer in China. With annual production of over 100 million spare parts for Tier-1 companies and 30 years of experience in serving our customers. Kingtime has gained substantial industrial experience in simultaneously engineering, raw material sourcing, precision forging, isothermal normalizing heat treatment, advanced machining, and complex assembly. The operation consists of a Hot Forging Division, Precision Forging Division and Driveline Division.

Learn More >