技术卓越

凭借多年的技术经验,我们的技术团队拥有扎实的理论基础和先进的实验方法,可以为您提供一站式的技术服务,例如CAE仿真。 我们可以进行同步研发,并为您产品的创新设计想法提供最佳的技术支持。 金泰还拥有使用电子显微镜和金相显微镜等多种分析技术来应对材料失效、材料性能挑战等,以便制造更轻,更坚固和更高性能的部件做好充分的准备。

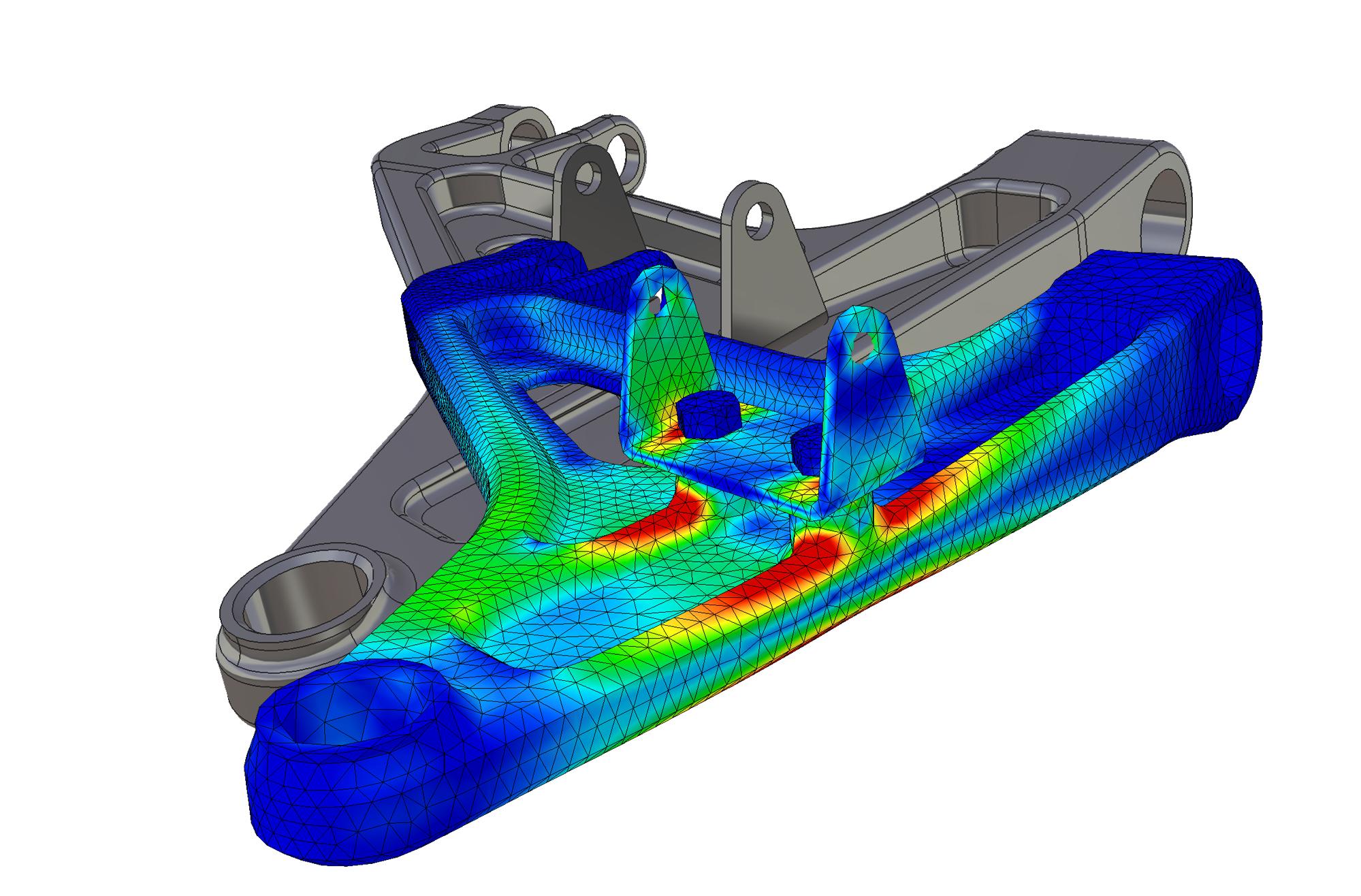

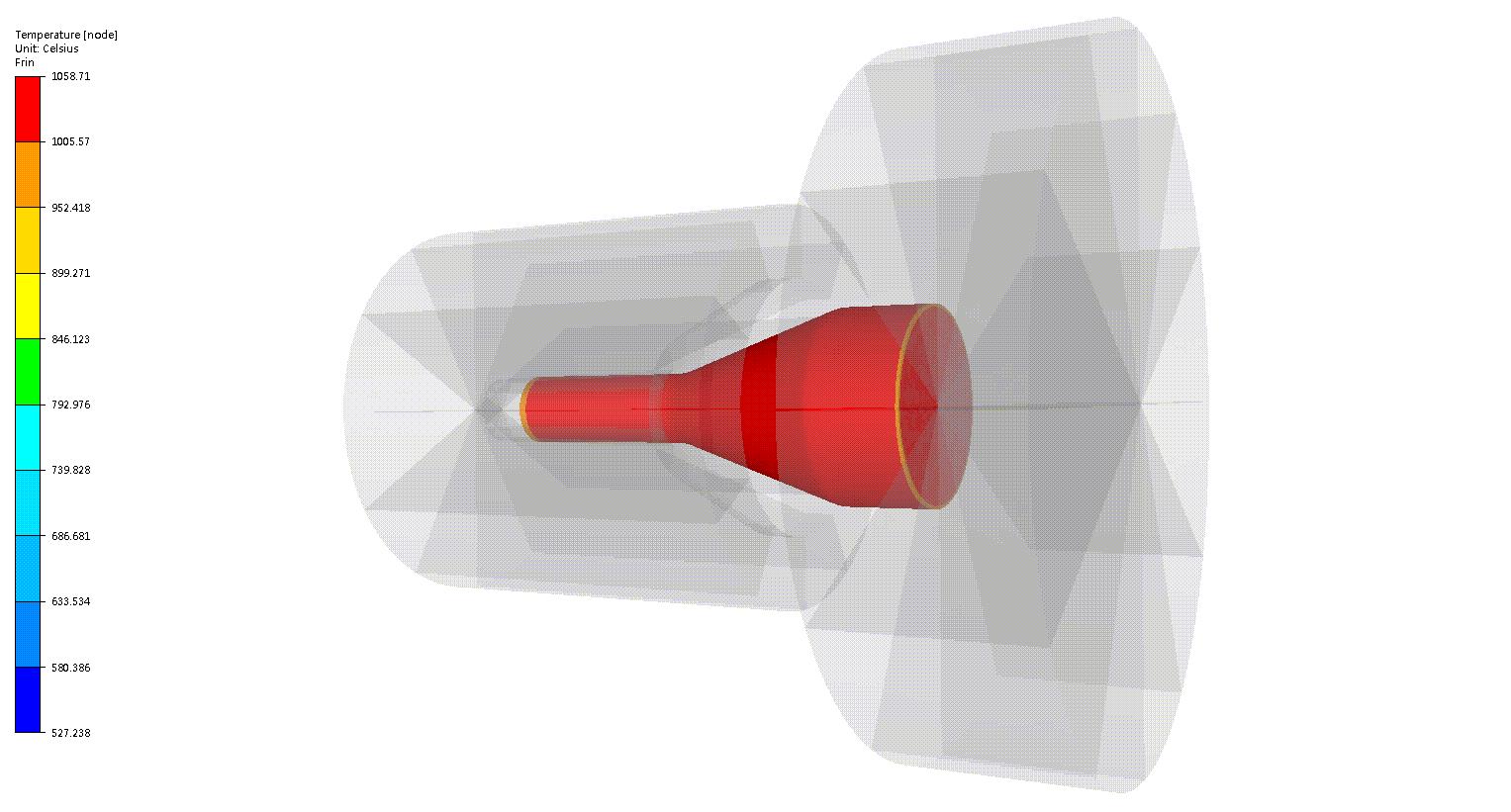

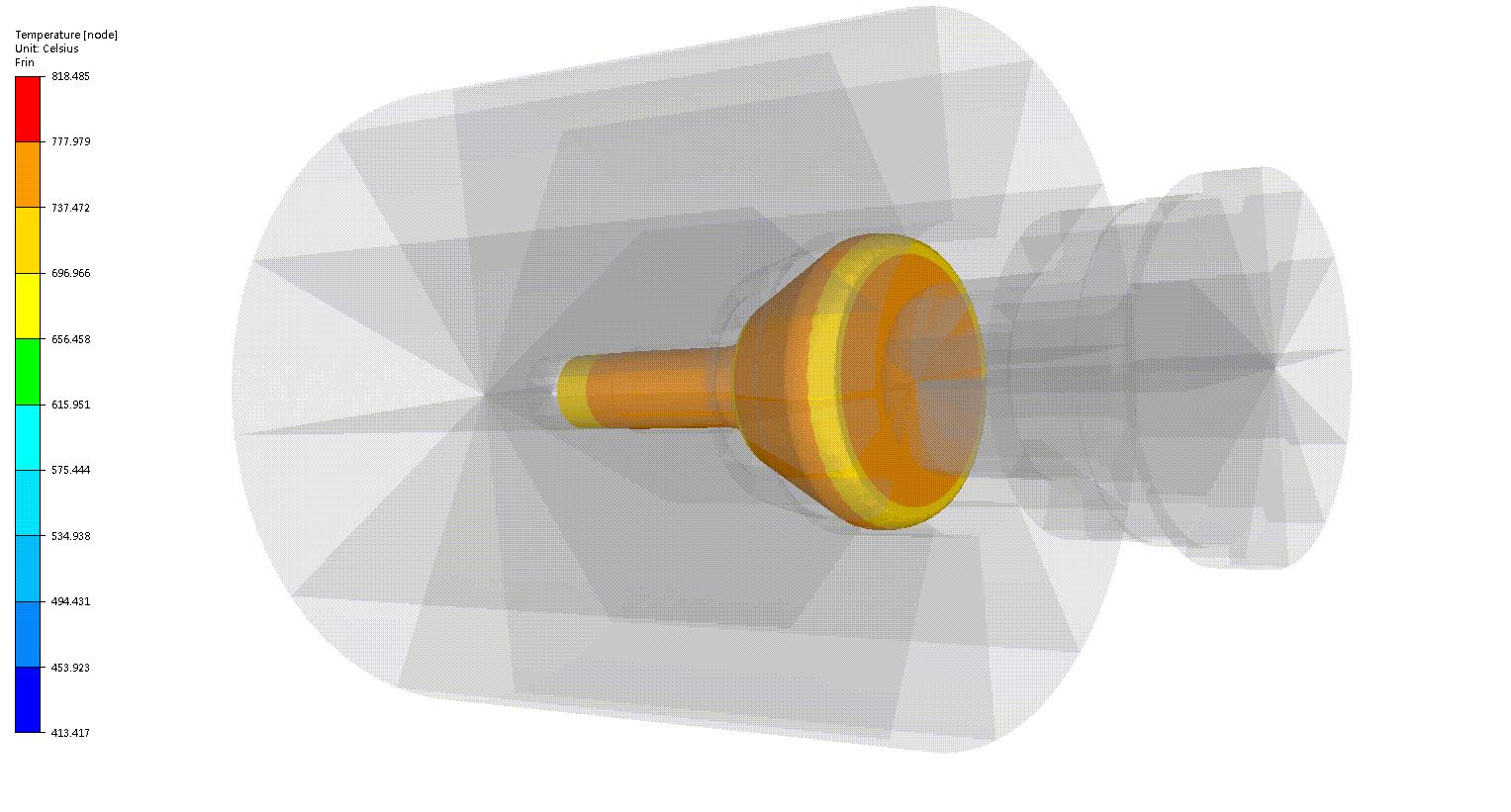

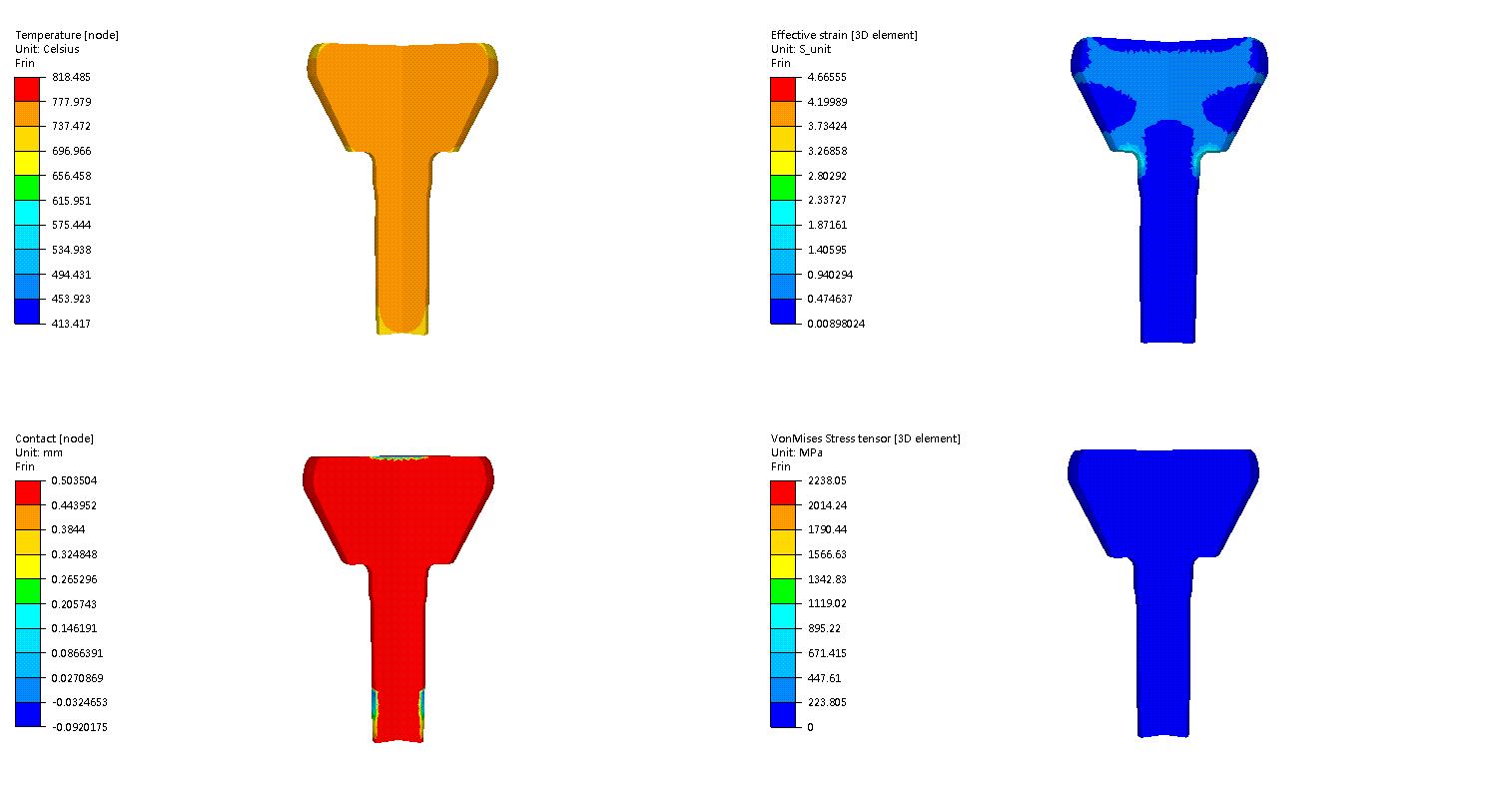

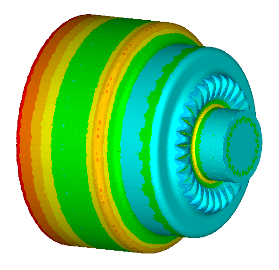

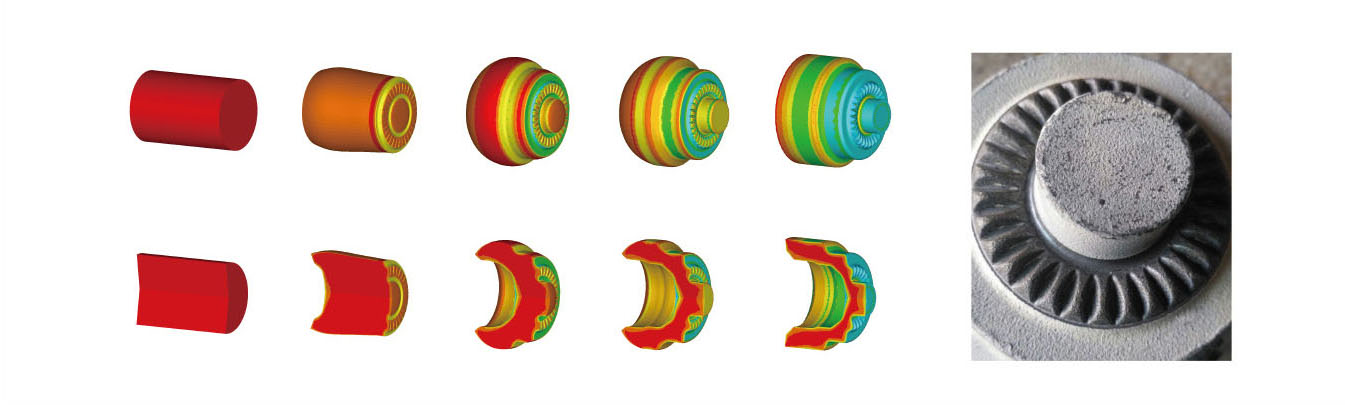

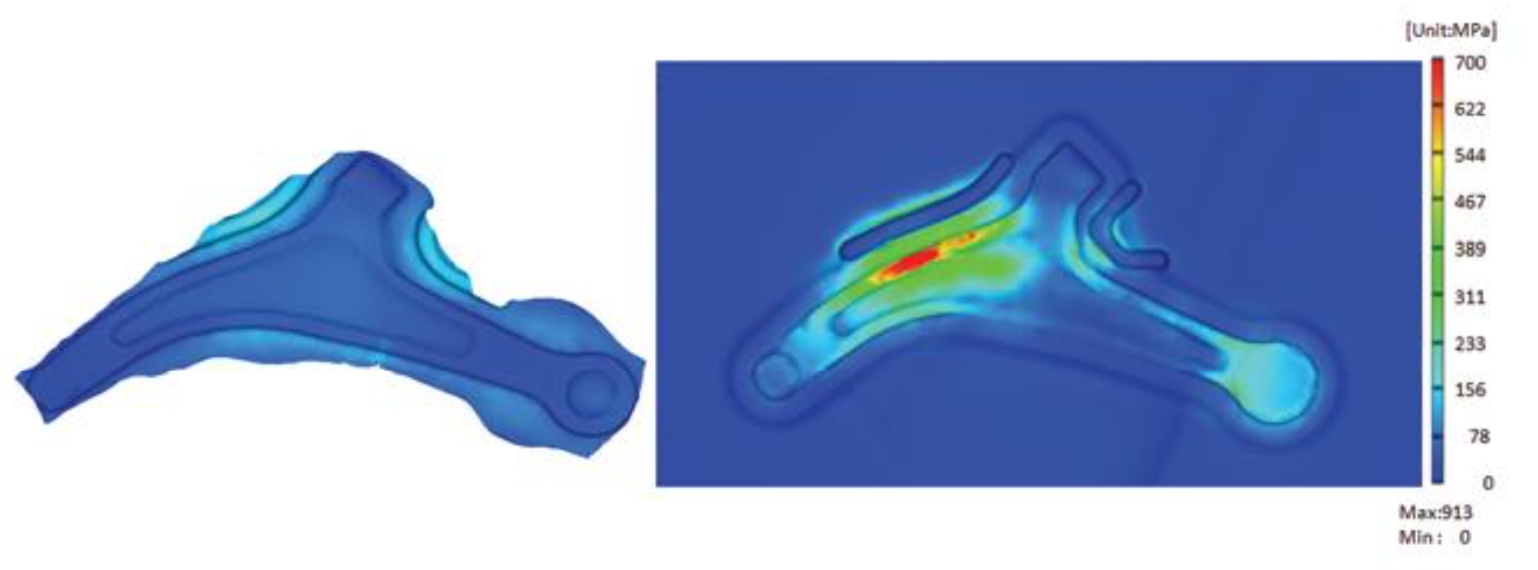

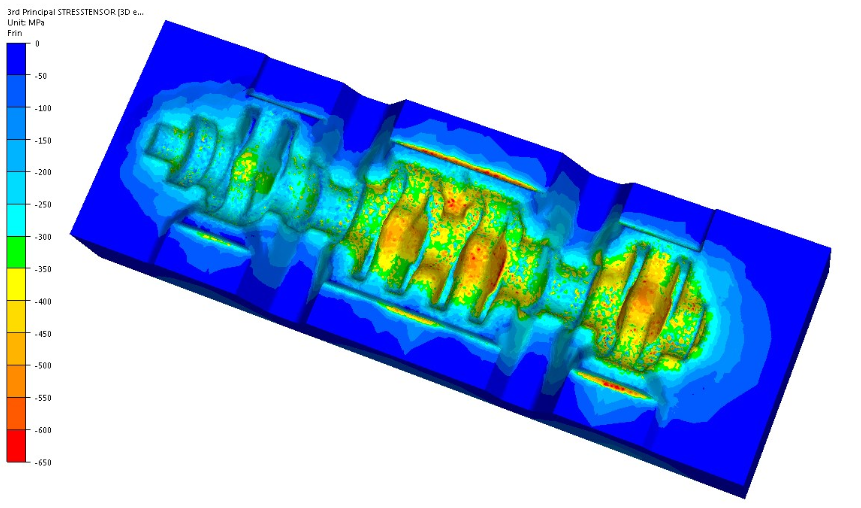

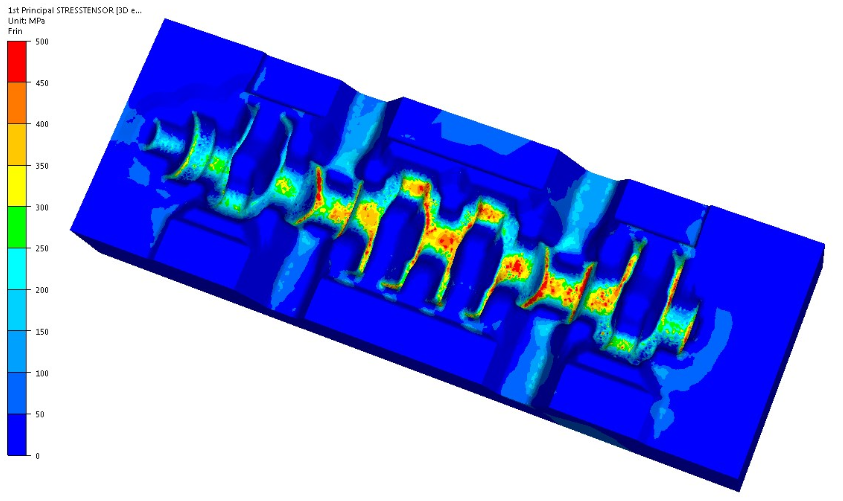

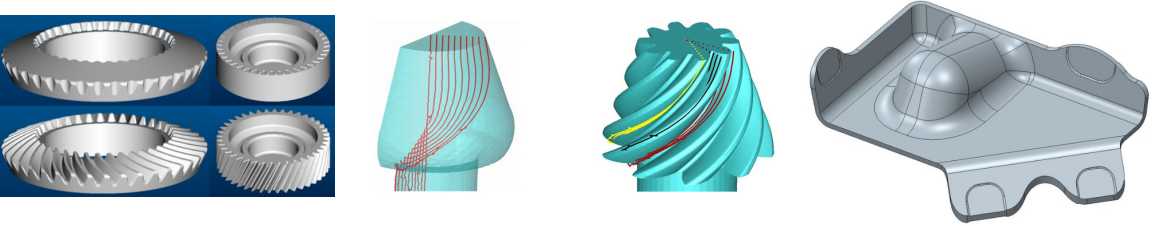

CAE仿真技术与应用

理论与实践相结合的科学制造经验

产品拓扑结构优化

模具结构设计、分析与制造优化

制造过程优化

齿轮冷热精密锻造

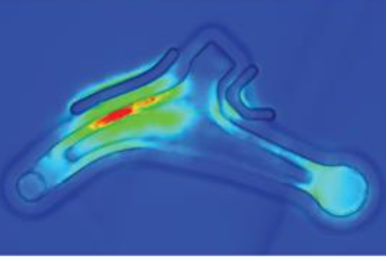

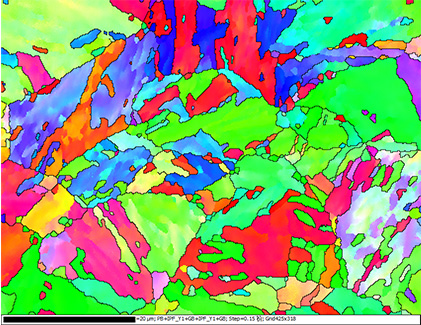

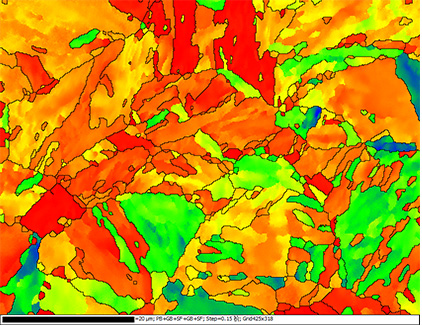

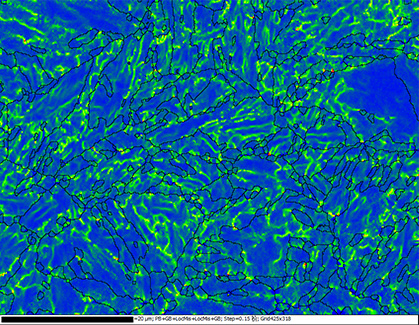

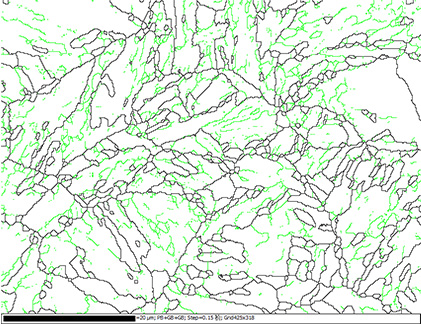

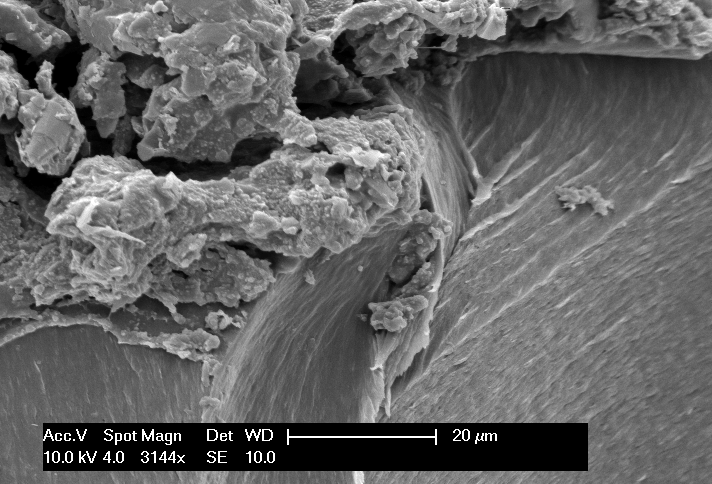

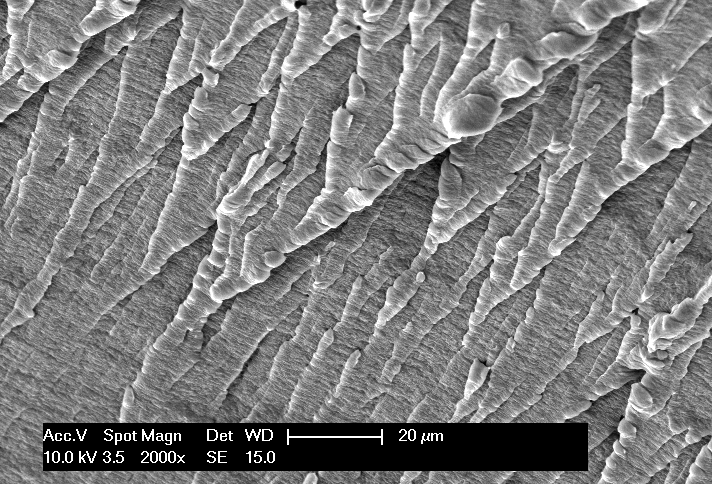

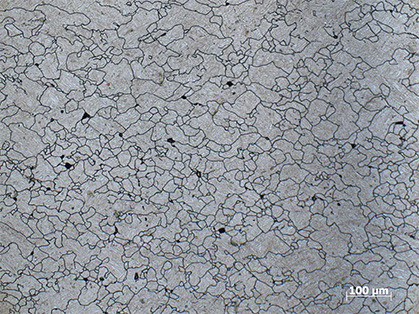

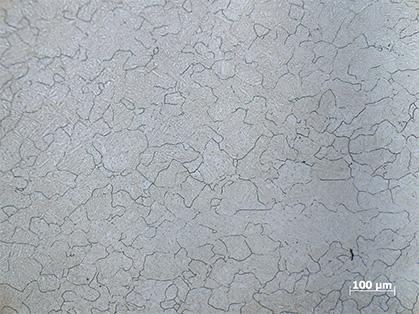

材料分析

晶粒取向,几何必要错位,施密特因数,高低边界等

拉伸断裂的微观形态

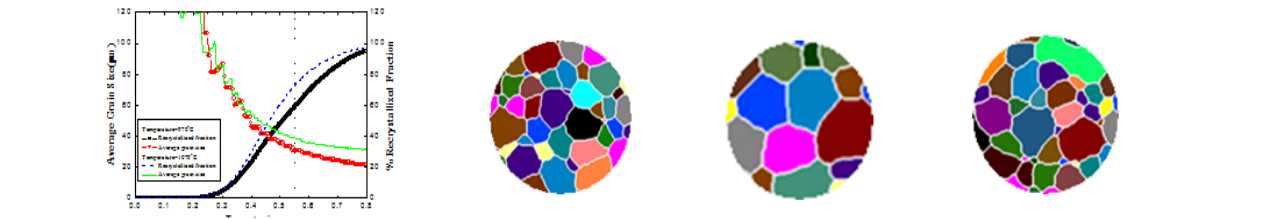

锻造过程晶粒尺寸的演变

微观组织结构演变